what does hardness testing determine|different types of hardness testing : broker Hardness Testing Basics. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the . Jogos grátis para PC, para jogar online a partir do seu comp.

{plog:ftitle_list}

webCuphead é um jogo clássico de plataformas e tiros em 2D, intensamente focado nas batalhas contra chefões. Inspirado por desenhos dos anos 30, o visual e o áudio foram detalhadamente recriados com as mesmas .

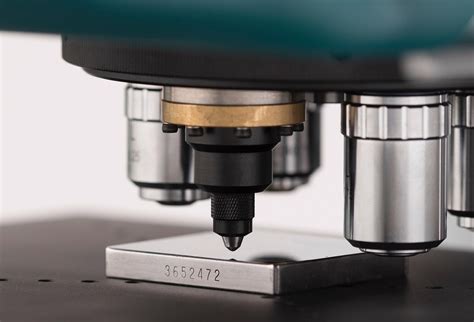

What Is Hardness Testing? Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications .Around 1900, Martens proposed the following definition for hardness testing: “Hardness is the resistance of a body to the indentation by another (harder) body.” This simple but precise definition has taken its place in technical .A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by . Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. This article discusses methods and the principles behind hardness testing.

Hardness Testing Basics. Hardness is a characteristic of a material, not a fundamental physical property. It is defined as the resistance to indentation, and it is determined by measuring the .A Comprehensive Look at Hardness Testing Definition. In more in-depth terms, hardness testing evaluates the hardness level of a material by measuring the depth or area of indentation .

The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to measure it. . It is commonly .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

why is hardness testing important

All hardness tests involve the utilization of a particularly shaped indenter that is harder than the material under testing. The indenter is pressed onto the test surface with the use of a certain amount of force. The size of the depth of the indent is measured in order to determine the hardness value. Hardness tests are beneficial because: The . Metal Hardness Test: Use Case: Formula: Results: Rockwell Hardness Test: The Rockwell test method is widely used due to its simplicity and speed. It employs a cone-shaped or spherical indenter. . Instead, they can determine the hardness of metals using standardized charts or rely on trusted suppliers to provide the correct metal for the .A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .

You can determine the hardness of your water by conducting a water hardness test using either the titration or test strips method. 13. What is the ideal level of water hardness? The ideal level of water hardness is a matter of personal preference. However, water with a hardness level of between 60-120 ppm is considered to be optimal for most .

Before application of the Rockwell hardness test, you must prepare the surface of the material to be tested. The required surface condition for the Rockwell hardness test depends on the load used. The Rockwell hardness test is used for macro hardness tests, which are generally defined as tests that use indentation loads below or equal to 1 kgf. A: Hardness tests determine how hard or soft a metal is by evaluating either penetration depth or indentation hardness. It does not define the basic nature of any physical property but indicates the wear resistance capabilities of materials.Hardness Testing Considerations The following sample characteristics should be consider prior to selecting the hardness testing method to use: • Material • Sample Size • Thickness • Scale • Shape of sample, round, cylindrical, flat, irregular • Gage R & R Material The type of material and expected hardness will determine test method.See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .

What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched". A list of the Mohs Hardness Scale Minerals is shown in the table below. Common hardness testing methods are introduced below. Rockwell Hardness. This method tests the hardness of steel parts by applying loads to parts via either a tungsten carbide ball or a spheroconical diamond indenter. A part’s testing surface and seating surface must be properly prepared prior to testing.Applications of Rockwell Hardness Test. Quality Control: Commonly applied in industries that require hard materials on parts and other manufactured products. Material Selection: This tool supports the process of identifying materials that will be applicable depending on the hardness needed. Heat Treatment Evaluation: Using the assessment of the hardness of the treated .

The oldest of the hardness testing methods in common use on engineering materials today is the Brinell hardness test, invented by Dr. J. A. Brinell in Sweden in 1900. The Brinell test uses a desktop machine to apply a specified load with a hardened sphere of a specified diameter. . The Brinell test is frequently used to determine the hardness . One key to identifying mineral species is to test its hardness. Mineral hardness tests can be performed at home or on a rockhounding field trip. There are necessary tools for express hardness testing: A fingernail, a . Hardness testing is a mechanical test that measures a material's resistance to indentation, scratching, or abrasion. . The hardness test is a way to assess the quality of a material, determine its properties, and evaluate its .

Research and Development: Hardness testing is used to develop new materials with improved properties. Failure Analysis: Hardness tests can help determine the cause of failure in materials and components. Abrasion Resistance: Hardness tests help determine a material's ability to withstand wear and tear caused by repeated contact and friction .

In eddy current testing, a current is introduced to the material. Changes in the current based on the material provide valuable workpiece information such as flaws and surface cracks. Eddy current testing can also be used to determine material hardness as well as material and coating thickness determination. Rebound Testing

It finds applications in fields like construction and heavy machinery, where quick and non-destructive testing is beneficial. Each type of hardness test offers insights into different aspects of a material’s properties. Scratch hardness is more qualitative and useful for comparative analysis in geology and gemology. In fact, there are many hardness tests, such as the Brinell, Knoop, Rockwell, and Vickers tests, that aim to obtain approximations of hardness of one material relative to other materials. Brinell Scale. The Brinell Scale was the first widely-used and standardized scale to determine the hardness of a material. The Rockwell Hardness test is a widely used method to determine the hardness of metallic materials, thanks to its simplicity and quickness. This hardness test is based on indentation and depth of penetration, and it can be performed on various metals, including aluminum, copper alloys, brass, soft steels, and hard carbon steels.

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the . Hardness testing is qualitatively and quantitatively discussed with particular references to the various types of hardness tests. Impact testing is also explained, including the mathematical relationship to calculate the impact energy. . is the most fundamental test to determine the tensile mechanical properties of a material. Prior to .

types of hardness testing methods

Besides the Mohs hardness test, there are other newer ways to test the hardness of materials. Popular ones are Vickers, Brinell, Rockwell, Shore, and Knoop. All these methods use an indention test to determine hardness. By measuring indention size and considering the force applied, it is possible to compute hardness. However, each method has .

Hardness testing of welds can be performed on any Vickers micro hardness testing machine. When hardness testing of welds, a series of measurements are made in a given pattern at a specific distance from the sample edge or top of the weld. The progression of the hardness values can then be plotted in a graph. Methods typically used: HV5 and HV10hardness tests - the Rockwell test is a measure of the resistance of material, specifically metals, to permanent indentation. Indentation hardness is not a fundamental . determine if the material was disturbed or if a bulge exists. If so, the material was not sufficiently thick for the applied load, resulting in a condition known as ‘anvil . Hardness testing is widely used in a multitude of industries and plays particular significance in structural, aerospace, automotive, quality control, failure analysis, and many other forms of manufacturing. . In manual dial gage testers ASTM correction tables must be referenced to determine the correct factor to adjust by. Alternatively, and .

single yarn strength tester principle commercial

load hardness tests vs depth

Live22. Play’N Go. Microgaming. Onetouch. Playtech. YGGDrasil. Game Online site Halus Bet777 Mudah Menang Jackpot dengan maxwin tertinggi dalam setiap permainannya dengan dukungan RTP Live terakurat.

what does hardness testing determine|different types of hardness testing